| East industrial Zone, Anping, Hebei, China – Anping County – China, Bohai Bay | 863185111380 | |

| http://www.sintered-mesh.com | ||

| Industry > METALS, minerals, scrap, virtual, holograms, APPS... | ||

| Anqing (China, close Shanghai) - Albuquerque (USA, Central) | Anqing (China, close Shanghai) - Albany (NY) (USA, East Coast) |

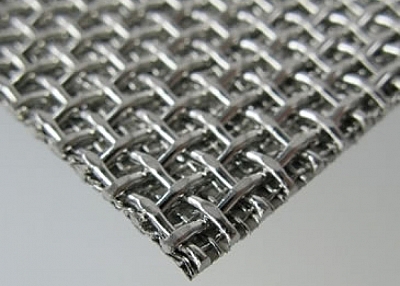

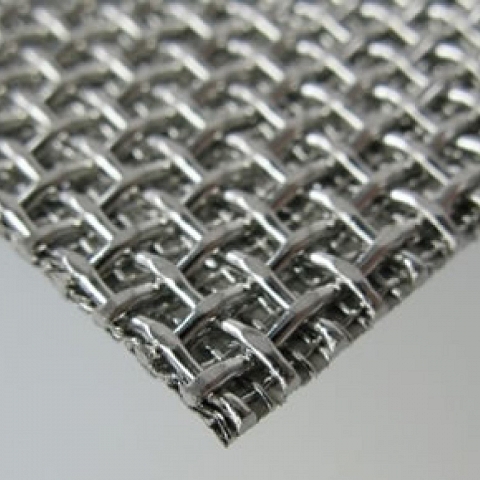

Five-layer sintered mesh is a standard combination of five layers wire meshes with different openings and diameters through sintering (diffusion-bonding) in vacuum, which improves the characteristics of stainless steel woven wire mesh. By bonding the contact points of different wire meshes together, five-layer sintered mesh has become an integrated porous material with enhanced mechanical strength, high permeability and better structural integrity, because the sintering process remains the good filtration rating of the finest mesh layer, also the mechanical strength of the coarser support layers. Besides all of that, heat and pressure are combined to create molecular diffusion-welds at every intersection of the wire mesh where the wires cross over and under one-another, which in turn enhances the temperature and pressure resistance of the sintered mesh. For its distinct features, five-layer sintered mesh is widely used for diffusing, breather vents, filters in many areas such as gas distribution, polyester filtration, water treatment, etc.

Boegger Industrial Limited-Sintered Mesh

Activity: Manfacture

What is sintered mesh? Sintered mesh is manufactured from one layer or multiple layers of woven wire meshes by a "sintering" process. The single layer woven wire mesh is first roller flattened uniformly, to ensure good contact at the wire cross over points. Then the single layer or more layers of this calendered mesh are then laminated by special fixtures under mechanical pressure in high temperature furnace, which is filled with proprietary inset gas and the temperature is raised to a point where sintering (diffusion-bonded) occurs. After controlled-cooling process, the mesh has become more rigid, for all the contact points of individual wires bonding to each other. Sintering improves the characteristics of woven wire mesh through the combination of heat and pressure. Sintered mesh can be single layer or multiple layer, according to filtration need, one layer of perforated metal can be added to reinforce the whole structure. What's more, sintered mesh can be cut, welded, pleated, rolled into other shapes, like disc, plate, cartridge, cone shape. Compared with traditional wire mesh as filter, sintered mesh has prominent advantages, high mechanical strength, high permeability, low pressure drop, wide range of filtration rating, easy to backwash. Although the cost seems higher than traditional filter, but its long using life and excellent properties gain more popularity with clear advantages. Our main products include: Five-layer sintered mesh, Sintered mesh laminate, Sintered mesh with perforated metal, Sintered metal filter cartridge, Sintered metal filter disc, Pleated sintered mesh filter, Sintered cone filter, Sintered metal fiber felt.